Introduction

Today it's more important than ever to automate the production. We offer vision systems with latest technology to help you automate your inspection. Since 2000, we have helped companies to improve their production through the most powerful solutions in vision technology available today. Vision System DV-2 is made in Sweden and continually developed in cooperation with the industry. Together with our customers who are active in most industrial sectors we develops the most effective solutions whether it is standard or advanced special projects. We have extensive experience of developing and installing vision systems and has built up thorough knowledge of industrial needs. Since we have full control of the software we can solve vision problems where others fails. We have partners in robotics and mechanics with experiences of our systems. They also provide complete automation solutions with vision DV-2.

Company

diVision AB are specialists in vision technology with many years of experience in vision systems, image processing and software development for industrial applications. We are located in Vellinge, just south of Malmö, Sweden. Our facilities are suitable for development, testing and design. diVision AB has highest financial rating according to UC and Soliditet (AAA).

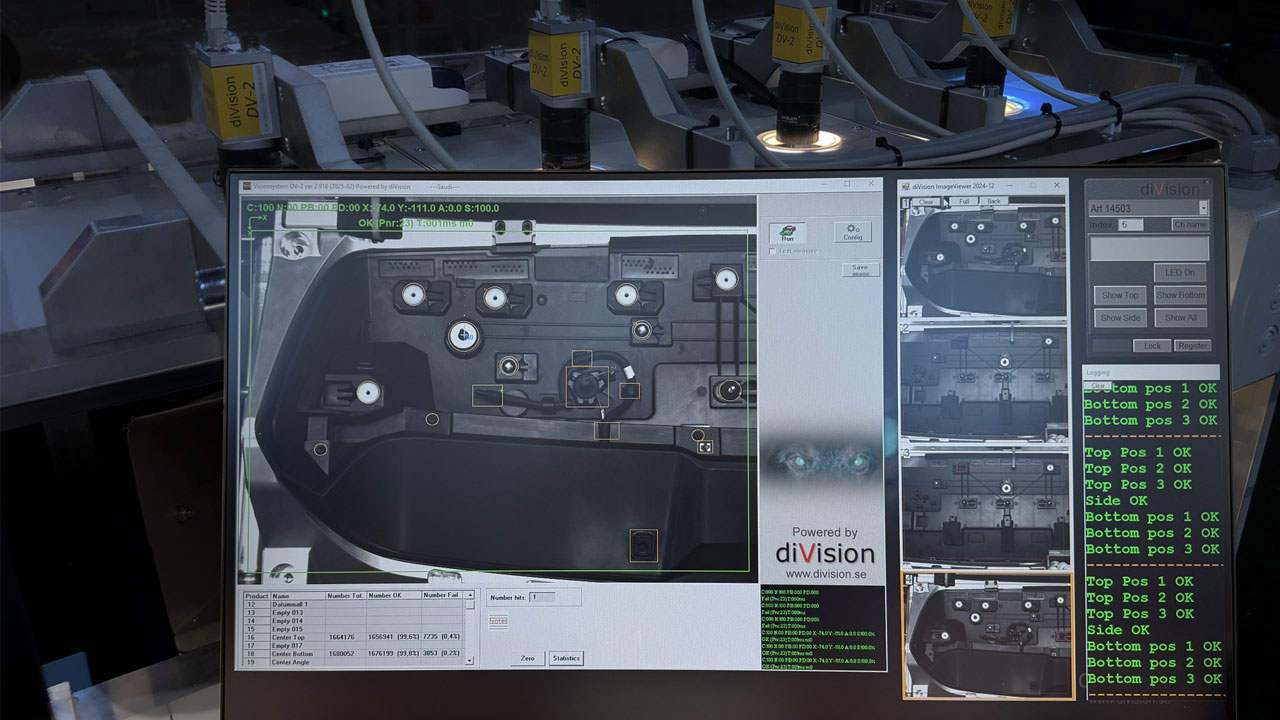

Vision system DV-2

Vision System DV-2 is configured easily for the current task. This makes fast startups, leading to lower investment costs. There are no menus and other difficulties that makes the system unnecessarily complicated to use. DV-2 is easy to understand. Forget all about being an expert on vision systems to realize applications. DV-2 is based on point and click principle. There are no "tools" , thresholdings and such things as in outmoded vision systems. The system is PC-based with the latest computer technology and built around standard products. One or more cameras can be used. Because of the system's unique functions it can handle natural variations (variations in shape, brightness, position, rotation, tilt and so on) false rejections can be minimized. The operator does not have to configure the system endlessly. New requests and needs from customers continually driving development forward

Vision system- functions

diVision DV-2 is available in two configurations:DV-2 - Solves basically everything.

DV-2 Onecam - For applications with one camera.

The system provides useful feedback to the operator via the monitor, with statistics and evaluated images. Configuration is carried out directly in the system. It is therefore no need to use separate configuration-software or computer. Images are saved continuously during operation for easy adjustment and improvement of the configuration. There are simple backup and support functions to easily get help and avoid unnecessary visits. DV-2 is modular and because we have full control of software we can, if necessary, customize the system. Along with the module Controller you can relieve your robot or PLC by allowing the vision system to handle the logic for grabbing images, lighting control, control shafts, handling I/O, communication with the operator, barcode scanners, printers and more.

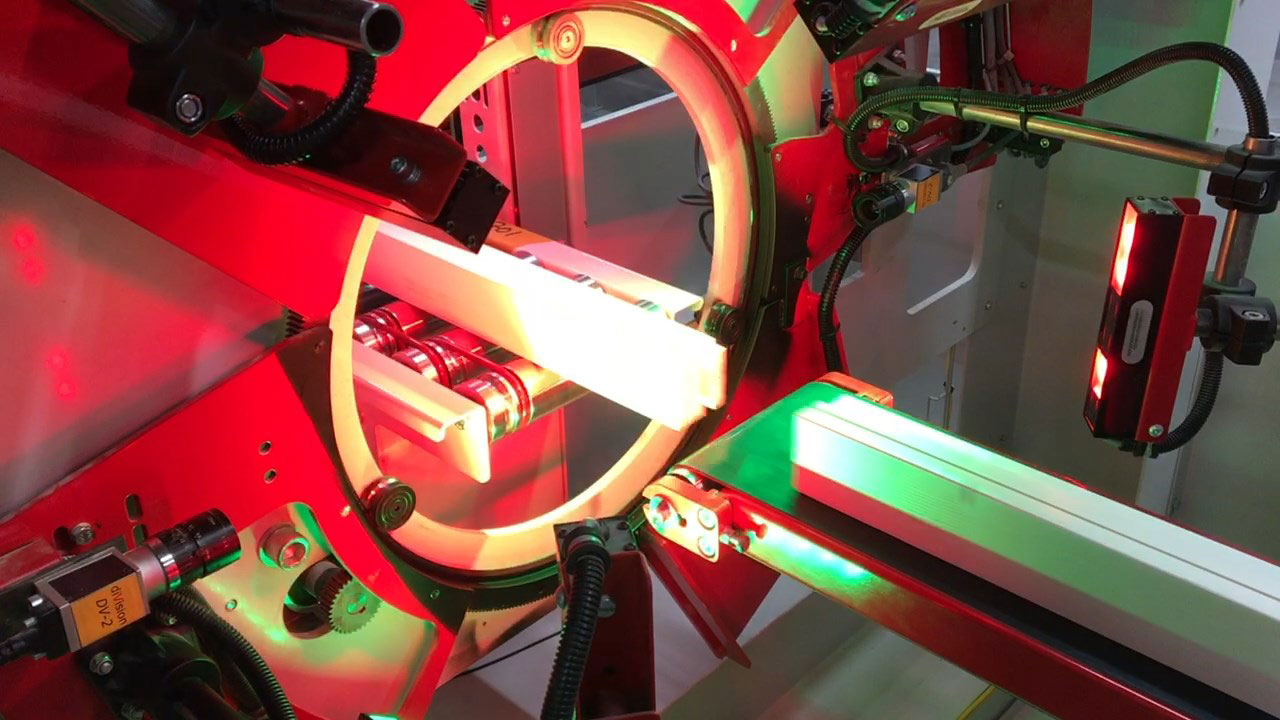

Applications- Quality control

Automatic quality control to inspect that the components are manufactured correctly, has correct shapes, correctly assembled etc. For inspection of products after manufacturing, assembling, injection molding, machining and more. Quality control can be complemented with measurements. Can also inspect printings as pad printing and screen printing. The vision system can be connected to robot, feeders, index tables, conveyors and more. The system can also be implemented in your existing facility.. Used to inspect everything from automotive and plastic parts to medicine and food.

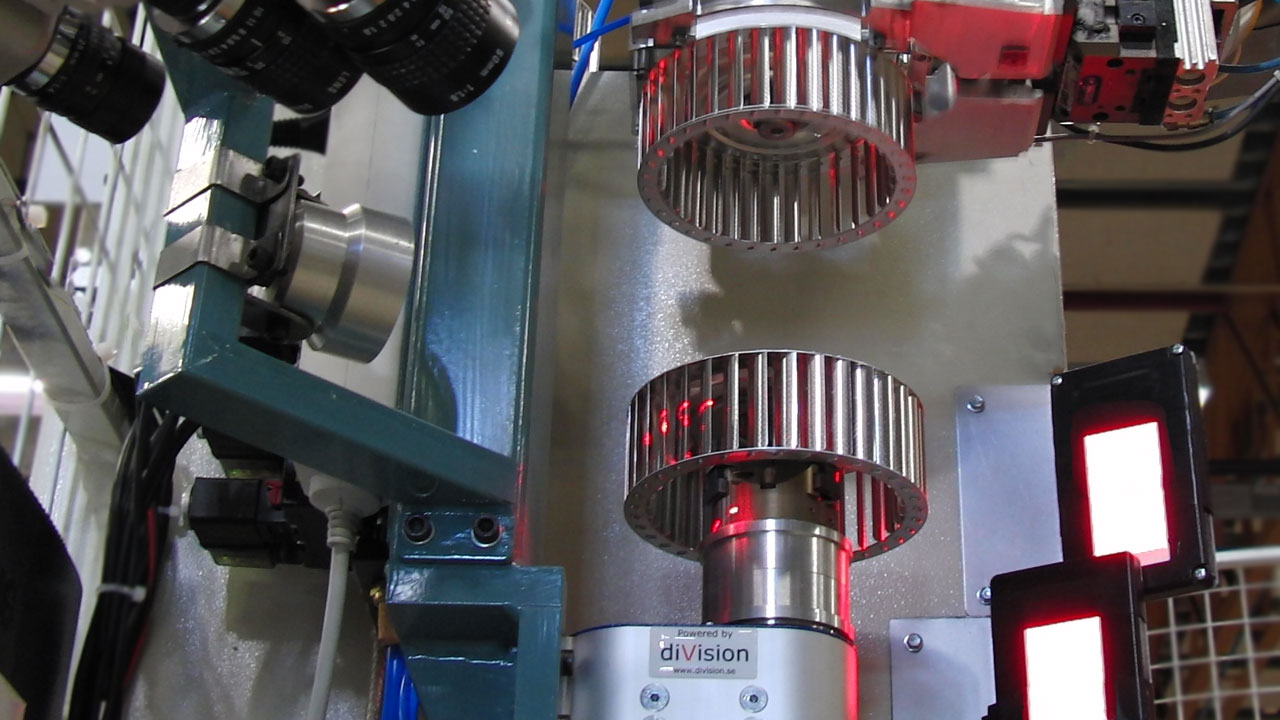

Applications- 3D Quality control

Automatic quality control in 3D. Part of our concept "Vision with motion" where we can control movements combined with vision. Here is used one or more linear movements to move the laser and camera in front of object or surface. 3D quality control is used to inspect parts where defects are not so visible in regular 2D (black / white, color). In welding can shapes, sizes, sinkings, "warts" etc can be inspected. We also have applications for finding slag etc. In bakery 3D and 2D scanning are done simultaneously to see the shape and size, cavities, lumps, brightness, compunded problems etc. Here is the camera / laser fixed mounted and the object is moved on conveyor.

Applications- Measure control

Automatic measurement to see the dimensions are within their tolerances. Measure for example. length, width, diameter. The values are scaled easily and tolerances added. Often used together with quality control. Logging of values can be exported to Excel and Rektron

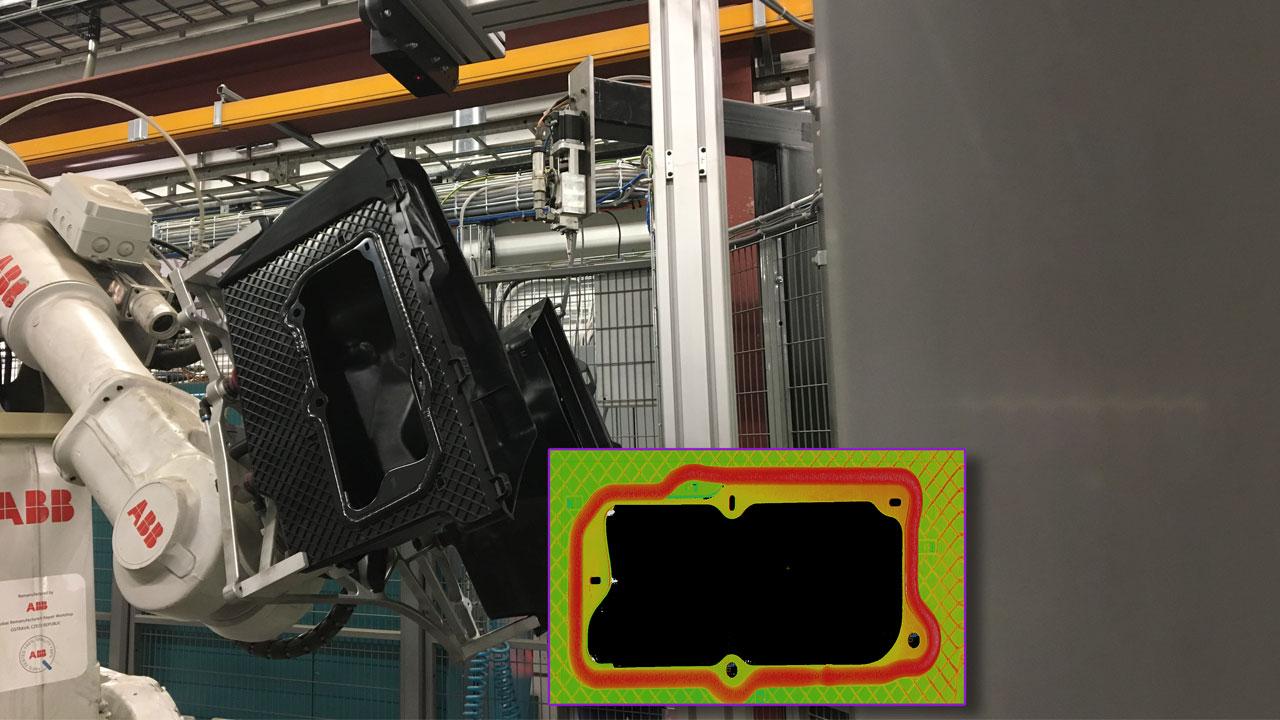

Applications- Advanced Measurements in 2D/3D

DV-2 can be used to make measurements of your products. Several cameras can be connected to the system to cover all views. Examples of dimensions are lengths, widths, diagonals, diameters, positions. By adding 3D dimensions it is also possible to measure flatness, inclination etc. A number of measurement points are measured in the system. These measurement points are used to do calculations and set tolerances in our calculation program. Can be used in robotic cells and manual manned stations. Full feedback with measurements, results and instructions to operator via the display. The system can be calibrated against a master.

Applications- Identification / Verification

Used to ensure that it is the correct product to be processed or packaged. With verification the robot / PLC asks if it is the right product and get OK or Fail result back. Identification tells the robot / PLC which product it is. The system handles variations on items such as glare and unevenness. Identification / Verification can also be done with 3D scanning for full flexibility. By checking at various detection points the product gets identified. You can also add dimensions of the product- lengths, widths, heights etc.

Applications- Robot guidance

Automatically get the coordinates and rotation of unsorted items. Can be used to pick everything from small clips to major details that are located in different pallet heights for machining etc. It is also possible for 3D-guidance where we also can get height, angle / tilt of the items. Robotguidance can be combined with quality control in the same system. We also offer our proprietary "Picco". It is a vision based standard solution for picking and sorting small objects. Available in a few different configurations.

Contacts

Contact us to discuss your project or to see the possibilities with vision system DV-2. diVision ABTerminalgatan 7

235 39 Vellinge

Sweden

Tel +46 40-140089

e